Execution of a Production Relocation to Romania During Ongoing Operations (PMI with Subsequent Site Closure)

as Interim Manager / Head of Production Relocation / PMI

Information about the Client / Employer

Company Type:

International Mid-sized Company

Industry:

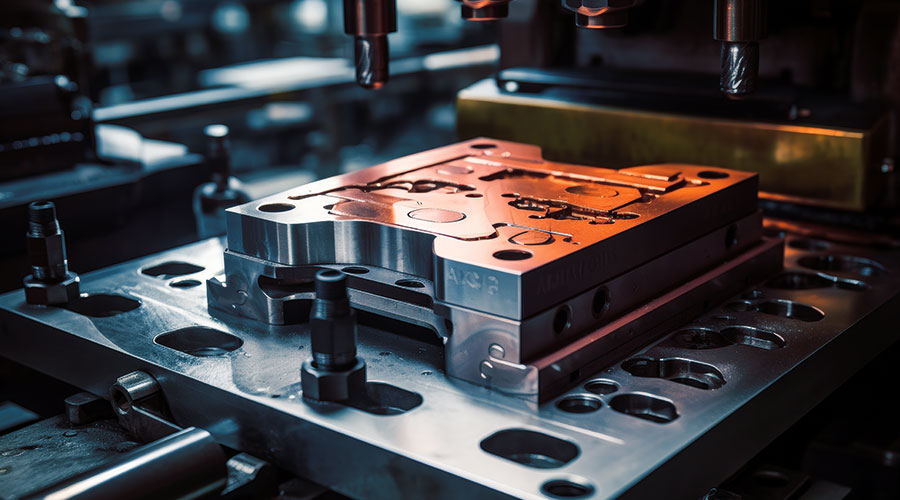

Lock and Hardware Technology / Aluminum Gravity Die Casting

Size:

- Revenue: approx. 65 million Euros at the affected plant

- Headcount: 78

Situation at the Client:

Production relocation of the acquired company during ongoing operations with subsequent site closure in Germany

- Acquisition of a German medium-sized company by the world market leader in the lock and hardware industry.

- The production of the acquired company is to be relocated to an existing plant in Romania after the acquisition.

- The site of the acquired company in Germany is to be closed after the production relocation. The employees are to be laid off.

- The production relocation is to be carried out during ongoing operations without interrupting supply chains.

- Remaining business processes, such as sales and product management, are to be integrated within the group.

Information about the Mandate

FRAMEWORK PARAMETERS

Role:

Project Manager International Production Relocation

Period (Duration):

01/2003 to 04/2004 (15 months)

Area of Responsibility:

Operational responsibility for the relocation of production with 78 employees at the acquired plant in Germany and subsequent site closure.

Assignment

Main Task:

- Development of a detailed project plan for the successive relocation of production to Romania while ensuring and maintaining ongoing operations.

- Setup of production in Romania. Ramp-up management. Closure of the site in Germany, implementation of personnel measures (layoff of approx. 60 employees), integration of remaining activities, such as sales and product marketing, into the buyer’s structure.

Sub-assignments:

- Project Budgeting, Identification and Assessment of Risks, Stakeholder Management, Transfer Pricing

- Ensuring stable and continuous business operations during the relocation

- Ensuring optimal quality, especially regarding polished surfaces

- Identification of critical products and ensuring supply capability through suitable measures

- Know-how Transfer to Romania and subsequent closure of the site in Germany

Measures

- Development of a detailed project plan for the successive relocation of production to Romania while ensuring and maintaining ongoing operations

- Project Budgeting, Identification and Assessment of Risks

- Identification of products critical for ongoing operations; Production of additional tools and molds to build up a suitable stock for critical products

- Creation of the production layout in Romania, training of Romanian employees at the plant in Germany, successive setup of production in Romania

- Know-how transfer by sending key personnel to Romania

- Setup of master data and production-relevant key figures in Romania, setup of manufacturing cost calculation, introduction of a transfer pricing concept

- Selection and setup of a supplier system in Romania

- Setup of a QM system in Romania

- Closure of the site in Germany, implementation of personnel measures (layoff of approx. 60 employees), integration of remaining activities, such as sales and product marketing, into the ASSA ABLOY site in Germany

Achievements

- Successful setup and commissioning of production without impacting delivery capability and ongoing operations

- Successful know-how transfer from the German plant to the receiving plant in Romania

- Optimized business processes at the Romanian plant regarding logistics, purchasing, lead times, quality standards

- Successful Post-Merger Integration of the remaining site

- Layoff of 61 employees in the course of the site closure

- Re-establishment of the warehouse system and optimization of the logistics concept at the remaining German site

Special Challenges

- Ensuring know-how transfer from Germany to Romania by employees who subsequently lost their jobs due to the site closure

- Ensuring and securing the supply chain during the relocation: Investment in additional tools and molds to build up stock for technically demanding products

- Complete re-establishment of the drawing structure and bills of material due to missing documentation

- Cultural Differences: unsuitable QM system and different understanding regarding the quality of treated surfaces

- Completely different management and leadership cultures, patriarchal leadership style at the Romanian plant, completely different value system compared to Germany

Share in Network